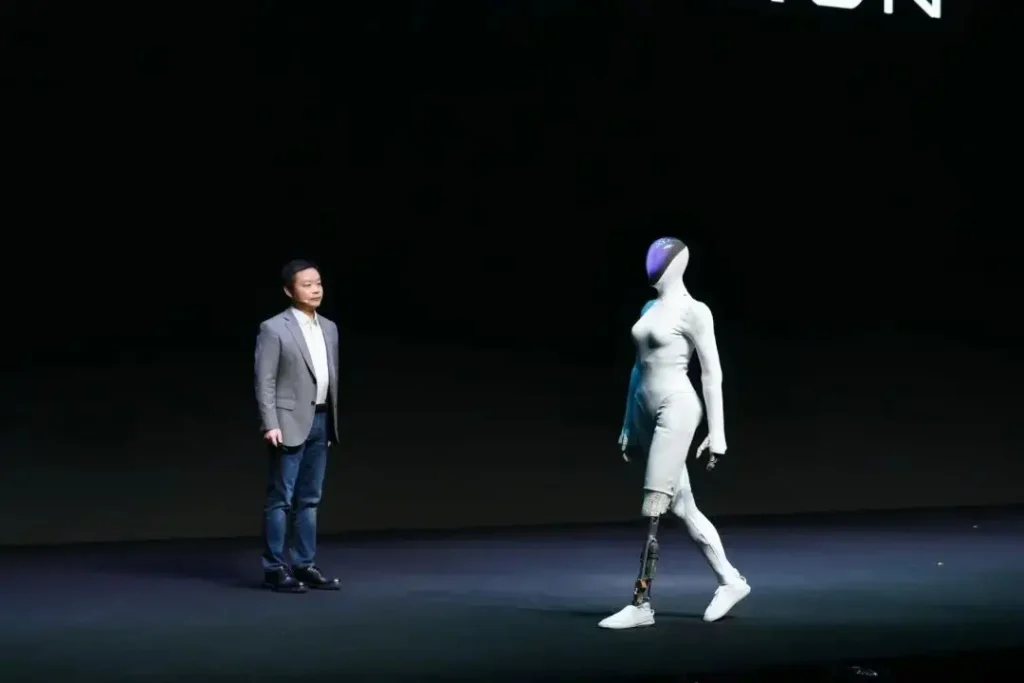

Next year will be a critical year for humanoid robot deployment. Currently humanoid robots are used in limited scenarios such as performances, interactions, and showroom guiding, but there are still bottlenecks to achieving “large‑scale delivery” in factories, and the industry is some distance from true industrialization. If humanoid robots are to enter households in the future, a host of more complex issues—standards and regulations, safety, user privacy, and so on—will need to be addressed.

Overall, the robot industry is moving from basic body manufacturing into more specialized and technically demanding areas. The industry will continue to extend upstream, evolving toward finer, more technology‑intensive directions, and ultimately build a complete humanoid robot industrial chain.

Next year will be a key year for humanoid robot deployment

Jiao Jichao, Vice President and Director of the Research Institute at UBTECH, believes next year will be a key year for humanoid robots to land. For the industry in general, and for UBTECH in particular, it is essential to find a genuinely deployable scenario that is replicable and scalable.

For humanoid robots, Jiao sees industrial scenarios as the first to achieve full autonomy. There have also been real commercial applications this year beyond dancing and performances, including guiding and presentations in 4S car shops and exhibition halls.

“Next year, full‑size humanoids will have more applications in these scenarios. In other industries, it will take 2–3 years for humanoids to generalize to more complex operations in industrial settings. For commercial roles that interact with people—like hotel service staff—the timeline is more like 3–5 years because of the greater complexity of human interaction. Household scenarios involve standards and safety issues; humanoids capable of working in homes will likely need at least 8–10 years.”

Pan Zhengyi, co‑founder and COO of Weiyi Zhizao, also believes AI will play a decisive role in future intelligent manufacturing. The core challenge for manufacturers today is that overreliance on automation can create rigid production that struggles to handle high‑variety, small‑batch flexible demand, while overreliance on manual labor causes efficiency bottlenecks and inconsistent quality. Deep integration of embodied intelligence technologies with industrial robots is the key to breaking the bottleneck—for example, robots that enable intelligent debugging and flexible multi‑operation switching can improve production flexibility, efficiency, and quality, truly driving AI’s deep deployment and value realization on the factory floor.

SenseTime co‑founder Wang Xiaogang says current large‑scale deployments of humanoid robots mainly provide emotional value—performances, interactions, and showroom explanations. Over the next three years, standardized scenarios such as industrial work and logistics sorting have the best chance of breaking through first.

In addition, with the development of autonomous driving technology, unmanned logistic vehicles are entering a phase of rapid adoption and will help solve last‑mile delivery challenges. They can autonomously handle loading, sorting, and other tasks and are suitable for highly standardized, high‑volume scenarios like forward warehouses and quick‑commerce warehouses. Yet scaling them up still faces the core challenge of accurately recognizing and handling thousands to tens of thousands of SKUs, which places very high demands on machine vision and cognitive decision‑making.

Xu Jincheng, founder and CEO of Pasini Perception Technology, is optimistic about the near‑term deployment of small proximate humanoid robots. “Small humanoid robots are already widely deployed in entertainment and education. They could enter factories within about five years.”

Li Tong, founder and CEO of Qinglang, highlighted export opportunities for Chinese robot makers. “At this critical juncture, robots are entering factories and daily life worldwide at scale, providing an unprecedented export window for Chinese robot companies.”

Li added that in the AI era, China’s accumulated manufacturing and scenario advantages are converting into export advantages. “As hardware carriers of AI, robots can offer internationally competitive solutions across manufacturing, logistics, healthcare, and service sectors.”

Bottlenecks to large‑scale humanoid robot delivery remain

Li Zhiqiang, founder and CEO of Yimu Technology, told Kechuangban Daily that the core of embodied intelligence is humanoid likeness, which requires a full perception‑decision‑action closed loop. Perception capability is indispensable and extremely important. Yimu previously released the world’s thinnest commercially viable biomimetic visuo‑tactile sensor and already has hundreds of customers generating sales and cooperation leads.

He believes there are big opportunities for Chinese companies in emerging fields like visuo‑tactile sensors, but they must improve parameter performance and mass‑production capability—companies able to produce at scales of hundreds of thousands to millions are still scarce.

On industry trends, Li said the robot industry is moving from body manufacturing toward more detailed and difficult directions. “This year the trend is higher and more flexible degrees of freedom in hands. The industry will continue to move upstream, becoming more refined and technically sophisticated, eventually forming a complete humanoid robot supply chain.”

Li views the current bottlenecks to large‑scale humanoid delivery as significant, and true industrialization remains some distance away.

“Industrial tasks are not complex but are highly repetitive and demanding of precision—many traditional industrial arms already handle them. Such scenarios are not necessarily the most suitable for humanoid robots. Yimu is more focused on non‑repetitive, non‑standardized scenarios that require fine manipulation.”

On paths to deploying embodied intelligence, Pan emphasized that at the hardware body level, industrial robot body tech is relatively mature; the core now is integrating upstream and downstream ecosystem resources, such as partnering with end‑effector vendors, to enable flexible task switching and efficient adaptation across scenarios. On the algorithm side—perception, motion, and execution—the key is using algorithmic data to distill, replicate, and convert human craft knowledge so robots can move from “execution tools” to autonomous, learning, and adaptable “intelligent partners.” This is the key distinction between true AI and traditional automation.

Leng Xiaokun, chairman of Leju Intelligent, predicts that next year some industrial humanoid robot procurements could reach ten‑thousands of units. He expects related technologies to pass the “basically usable” threshold within roughly five years.

“But to truly enter our daily lives as consumer products will likely take about a decade,” he added. “Standards, safety, and privacy issues are far more complex and thorny than purely technical problems.”

World models favored

Currently, world models and VLA (Vision‑Language‑Action) models represent two parallel and complementary technical routes for embodied intelligence. Yimu’s Li Zhiqiang says there is no definitive convergence yet. “In the medium term, VLA models will serve as a supplement; in the long run, it will likely converge toward world models, but that depends on massive data training.”

Wang Xingxing, founder of Yushu Technology, prefers video‑generation‑based world models. He notes that current VLA+RL models still lack generalization ability; he favors world models built on video generation.

However, he also points out challenges for world models. “Small and medium robot companies have trouble running these models because video‑generation models are extremely compute‑intensive and require many accelerator cards. Currently, larger AI and internet companies have richer resources for video models, so they’re more likely to succeed.”

暂无评论内容